- +86 13570824123

- hr@sitec.cn

Drive air supply: 1~8bar;Output pre...

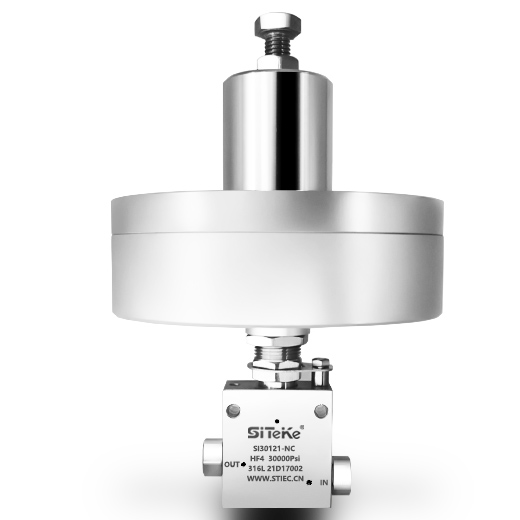

Manual control pressure genertor1. ...

Maximum working pressure: 60,000psi...

High working pressure: can be used ...

The hydraulic 10MPa (1450psi) is us...

Maximum working pressure: 60,000 ps...

Copyright © 2012-2021 Shenzhen Siteke Pneumatic Hydraulic Co., Ltd. Copyright 粤ICP备15051776号