Functional Characteristics

The handle designed according to ergonomics is convenient and comfortable to operate;

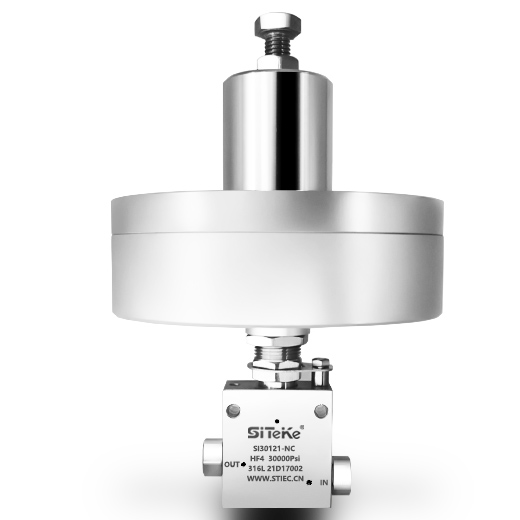

Unique split valve stem design solves the problem of integrated concentricity;

High quality alloy double thread design reduces the resistance of the knob;

Reliable anti rotation fixation;

Panel or bracket installation;

Special double thread engagement design makes operation more convenient;

PTFE packing has low friction and long service life;

The cold processed austenitic stainless steel 316 valve body makes the valve body more resistant to corrosion and wear;

Conical metal seal, which can completely seal whether the medium is gas or liquid;

The pressure relief hole and connection method shall comply with the international standard of high-pressure threaded connection;

The valve uses stainless steel nut, threaded sleeve.

Leading Feature

STK needle valves provide maximum safety and reliability, even under adverse operating conditions, the valve can be installed in any direction and can effectively seal the gas and liquid media The valve pin and valve stem are of a non-rotating design. Thus, the valve life and reliability are increased. Pressure parts are made of high quality corrosion resistant stainless steel All needle valves recorded the reliability of the serial number. Provide complete traceability of all pressure-retaining components.