Functional Characteristics

Standard material: 316, standard sealing material NBR, PTFE packing and nylon valve seat, inlet connection 1/4 "NPT, outlet 1/4" NPT, easy to adjust on site;

FRV series relief valves provide reliable exhaust. These precision valves are specially designed for pressure gas design systems, cryogenic systems, petrochemical applications and other special systems. Capable of handling air, gas and liquid;

FRV10/FRV20 relief valve adopts soft seat design, which can discharge gas reliably under the set pressure (3000 psi~21000 psi);

The soft seat design provides a good seal that can be popped and reset repeatedly. In addition, soft seated valves have a higher cycle life than metal seated safety valves, and are not recommended for liquid nitrogen or liquid carbon dioxide;

FRV30/FRV45 relief valve adopts metal seat design;

The opening of relief valve is proportional to the increase of pressure; Therefore, they are not recommended for applications where full flow of the valve is required immediately at the set pressure (e.g. decomposition, polymerization, etc.).

Leading Feature

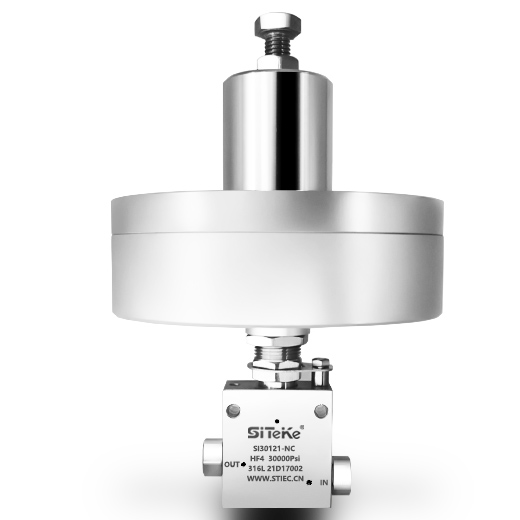

STK needle valve provides maximum safety and reliability. Even under adverse operating conditions, the valve can be installed in any direction and can effectively seal gas and liquid media.

The valve needle and valve stem are non rotating design, which increases the service life and reliability of the valve. The pressure bearing parts are made of high-quality corrosion-resistant stainless steel.

The reliability of serial number is recorded for all needle valves, and the complete traceability of all pressure retaining parts is provided.